CREEP FEED GRINDING

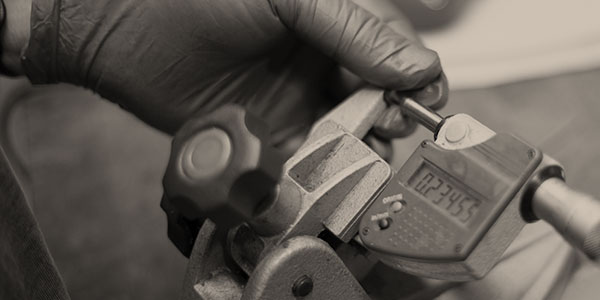

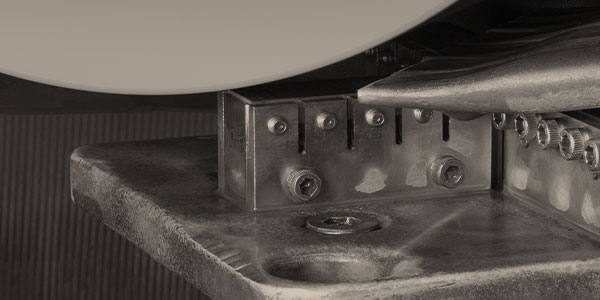

The Abrasive West Creep Feed Grinding Process cuts and finishes products in one movement, delivering highly accurate results with controlled depth and superior finishes.

THE ABRASIVE WEST DIFFERENCE

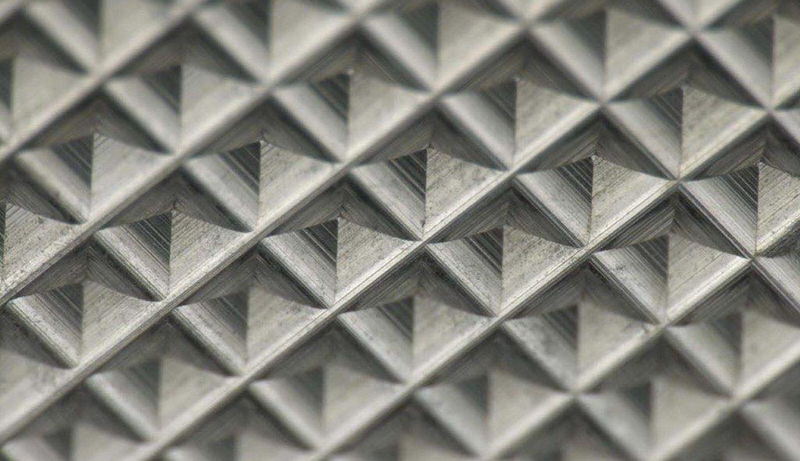

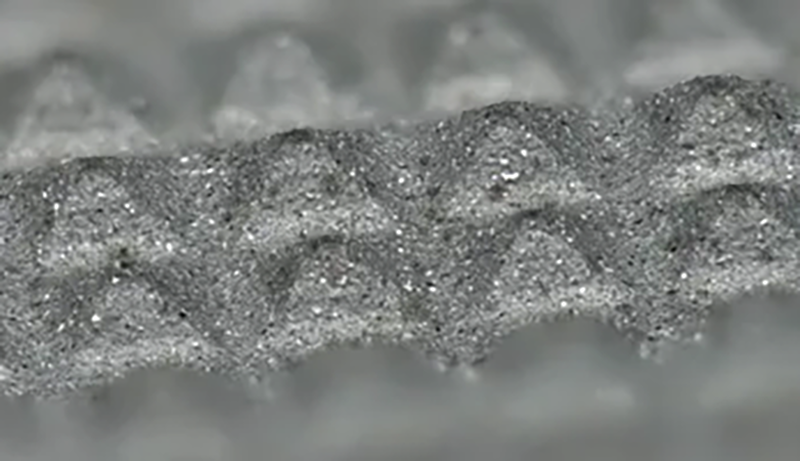

There is no comparison between Abrasive West's precision grinding on the left and the competitor's cast inserts on the right.

Photos: tungsten carbide inserts – digital microscopic photos

ABRASIVE WEST

GLOBAL LEADER FOR INSERTS