THE ABRASIVE WEST DIFFERENCE:

Precision. Performance. Delivered.

PRECISION

Operating with dependable accuracy.

Precision for You

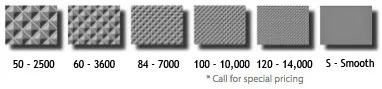

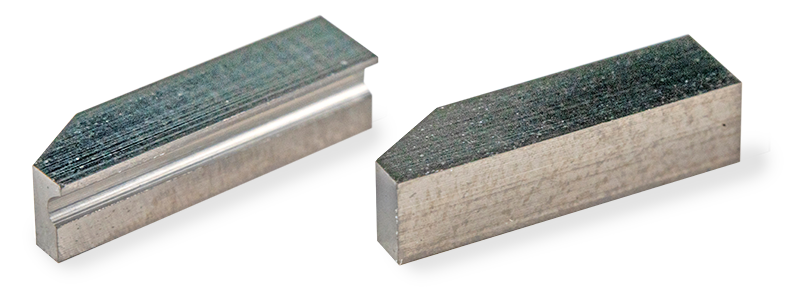

Surgeons can have faith in the integrity of these tungsten carbide inserts gripping the suture needle exactly and with less slippage than milled inserts or stainless steel instruments.

Precision for Us

Means starting with the highest quality tungsten carbide, employing creep-feed grinding methodology and rigorous quality control to ensure the highest caliber inserts. Our process, and 30 years of manufacturing experience for OEM’s and repair shops, yields tungsten carbide inserts that have optimal needle gripping power, superb wear resistance, consistency and greater productivity for the end user, your customer.

PERFORMANCE

Products with exceptional strength, durability and proficiency.

Performance for You

Performance for you and your customer means ordering a product that is efficient and uncompromising in fulfilling its intended purpose with exceptional strength, durability and proficiency.

Performance for Us

Performance for us means using our proven expertise, as we were formerly a department of Abrasive-Form, to meet or exceed the expectations you and your customers have for an exceptional quality insert, service and on-time delivery.

DELIVERED

Consistently delivering the highest quality tungsten carbide inserts on time.

Delivered for All

Knowing that you have acquired inserts that hold the exceptional precision, durability, and performance that is so critical to your business and the surgical instruments you provide to your customer. Abrasive West knows how important our inserts for the needle holder forceps are to a surgical instrument manufacturer.

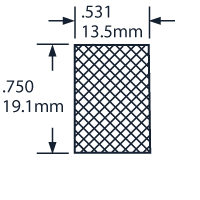

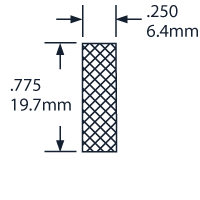

INSERTS

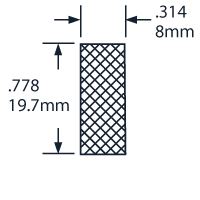

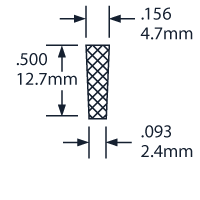

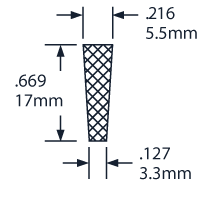

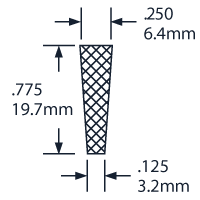

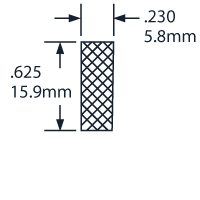

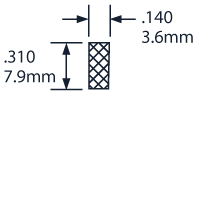

Standard Dimensions

Find standard trapezoid or rectangular insert sizes below. Stock availability varies. (.dwg file avail. on request.)

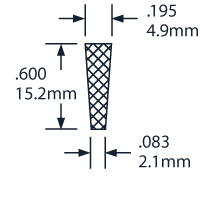

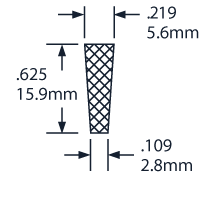

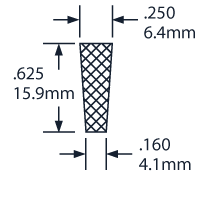

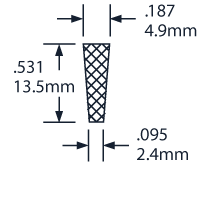

TRAPEZOID INSERTS

Part Number: 156

Part Number: 195

Part Number: 219

Part Number: 250

Part Number: 531

Part Number: 669

Part Number: 775-125

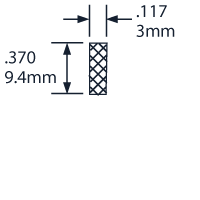

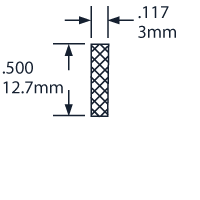

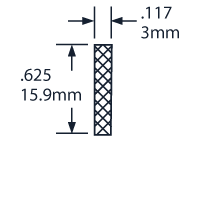

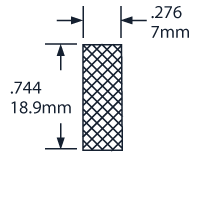

RECTANGULAR INSERTS

Part Number: 230

Part Number: 310

Part Number: 370-117

Part Number: 500-117

Part Number: 625-117

Part Number: 744

Part Number: 750

Part Number: 775

Part Number: 778